Generation 3+ hardware

In short:

Barefaced cabs are built tough for gigging and the Generation 3 finish and hardware was the result of much thought, experimentation and feedback based on the tens of thousands of gigs our customers have played. Durability is paramount! We have also made our electronics easily field-replaceable, for minimum stress on worldwide tours. If you gig a lot and want to keep your cab looking pristine we recommend purchasing one of our padded fabric covers.

And in full - it starts with our tough textured acrylic coating or heavyweight tolex...

All our 12XN enclosures have a thick textured acrylic coating - black is the standard colour. It is tougher than tolex, doesn't pick up hairs or bobble like carpet, wipes clean and can be easily touched up if chipped. For a more traditional look the 10CR range is wrapped in the best black tolex we could find.The corners are protected by three-sided metal corners at the rear and two-sided metal corners at the front.

New improved handles and sideways stacking

Before we started designing the new range we ordered numerous sample feet and handles from the two major cabinet/flightcase hardware suppliers in an attempt to find a more durable handle (the previous handles always remained functional but the ends of the rubber frayed which didn't look brilliant) and a small foot with the clearance to allow stacking over the handle with a rubber compound which still gripped well on slippery floors. The new strap handle has metal fittings and metal inserts on the strap ends so the rubber doesn't get worn and is strongly sprung so it doesn't rattle at high SPL. The new small feet are taller than before and provide slightly better isolation and grip on shiny varnished wooden floors which are prone to boom.

Feet and wheels

Our 1x10", 2x10", and most 1x12" cabs have small rubber feet on the base and one side opposite the handle, attached with long thick screws right through the plywood so they do not get knocked off. Our 2x12", 6x10" and 8x10" cabs have tilt and roll wheels on the back edge of the base and large rubber feet at the front edge, which are attached with bolts and t-nuts to survive the rigours of gigging. With the previous generation Barefaced cabs we had too many instances of foot screws being pulled out - our small feet used to be attached with shorter smaller gauge screws due to their location whilst our large feet used screws, not bolts. We are confident that this upgrade will solve this irritating problem: In the unlikely event that it doesn't then we'll think of something else - I don't want to hear of any more feet falling off!

Handles

The Super Midget, Super Compact, Big Baby 2, One 10 and Two 10 have a single strap handle on the side - the new small feet clear the handle so cabs can be stacked vertically or horizontally as the acoustics or aesthetics require. The Super Twin and Big Twin 2 cabs have three strap handles, one on each side for lifting the cab plus one on the top for wheeling it about. Our Six10 and Eight 10 have two recessed bar handles, one on each side for lifting the cab, plus a strap handle on the top for wheeling the cab about. Recessed bar handles would not work on our 2x12" cabs because they would restrict the air flow in the large side ports but fortunately the strap handles work very well due to the cab's low weight. The recessed bar handles are beneficial on the Six10 and Eight 10 because these cabs are wider and having your hands inside the cups reduces the chance of skinning your knuckles on narrow doorways.

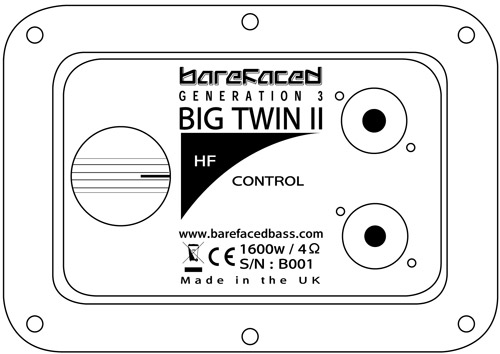

Controls and connections

All the Generation 3 cabs have black powder-coated steel connector plates, with the model information and serial number clearly printed and two parallel combi speakon + 1/4" sockets. These sockets accept a standard wired speakon (2 pole, 1+ 1-) or a standard wired mono 1/4" jack (tip positive). The Super Midget, Big Baby 2 and Big Twin 2 have a larger connector plate, onto which the crossover and high frequency control circuitry are internally mounted and the HF control knob (with dB markings) externally mounted. This connector plate, crossover and HF control circuit is a complete modular assembly - in the unlikely event of it being blown through overpowering it can be replaced in its entirely with just a screwdriver, without even removing the grill or loudspeakers. If the HF driver is blown through overpowering (again, very unlikely because the crossover contains circuitry to prevent this in 99% of situations), it can be replaced by removing the connector plate and either (with the BB2 & BT2) unbolting the neo compression driver from the back of the waveguide or (with the Super Midget) unscrewing the ferrite compression driver from the back of the horn - once again without needing to even remove the grill.

Steel grills

As standard, all our cabs, except for the Six 10 and the Eight 10, are now fitted with custom punched steel grills, which have a smooth satin black finish which is an enamelled powder-coat with much improved durability compared to our previous models. The grills have a solid border which is foam damped on the rear to prevent any extraneous noise and allow easy removal and replacement in the unlikely event of a woofer being blown (our previous grills generally required the foam tape be replaced whenever the grill was removed and refitted).

Cloth grills

The Six10 and the Eight 10 have a silver/black heavy gauge cloth grill which suits their vintage vibe - these grills are hand-stretched over a strong but lightweight CNC'd plywood frame and then finished with white piping to give a very professional yet retro look. The outside edges are then wrapped in black foam tape and the frame velcro'd to the baffle, with the foam tape ensuring a snug 'friction fit' which will never rattle or buzz. These cloth grills are also an extra cost option on all the other models (see all our prices here).